Inspected pieces:

585 pieces ⇒ 1,260 pieces (Increased by 675 pieces)

Productivity Improvement of Approx. 115%

| Electronic Components | |

| External Diameter Measuring Tool for Precision Pipe – CT-Effects Application Example |

|

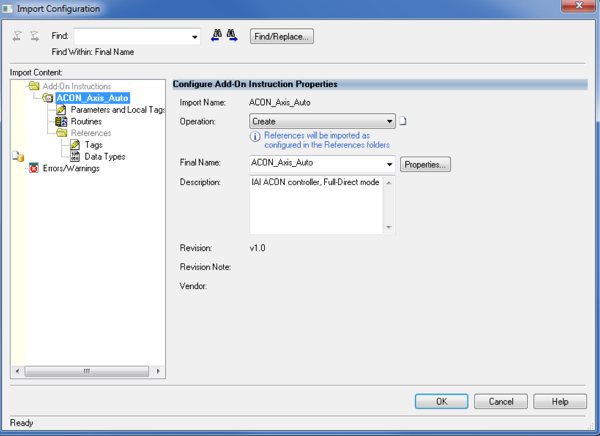

| [ Robot/Electric Actuators ] |

[ Controllers ] |

| ISPB-LXMX |

XSEL-P/Q/J/K |

[Equipment Detail]

An optical measuring tool moves along a pipe and measures the external diameter at a specific location (near center) of the pipe surface.

The cycle time was long and this was the bottle neck in the production line.

A pipe is placed and removed manually.

[Problem in Using an Air Cylinder]

The pipe length was 2,000mm, and the measuring action was activated by a sensor. As it was not possible to have a speed change on the way in order to obtain stability through constant speed operation, the instrument needed to have a low-speed operation through the whole stroke.

Line stoppage has occurred for 30 minutes a day due to measuring error.

[After Replacing to ROBO Cylinder]

Moving with high speed to the front of the measurement point, moving slowly to take measurement at the measurement point, then travel back to the home position with high speed enabled for shorter cycle time.

The measurement tool moves stably in constant speed, which ended with nearly 0 times of line stoppage due to measurement error.

By using the zone output signal, the sensor is no more needed.

Eliminating the bottle neck and improved the line productivity.

[CT Effects – Reduction in Cycle Time/Choco Tei]

| Subject | Instrument with Air Cylinder | Instrument with Electric Cylinder |

| Cycle Time | 40 seconds/piece | 20 seconds/piece |

| Duration of Line Stoppage | 30 minutes/day | 0 |

| Number of Work Pieces inspected in Line Operation Hours | 585 pieces (*1) | 1,260 pieces (*2) |

7-hour operation per day (420 minutes)

(*1) (420 minutes – Line Stoppage 30 minutes) *60 seconds/ 40 seconds/ piece=585 pieces

(*2) 420 minutes *60 seconds/ 20 seconds/ piece=1,260 pieces

See more IAI electric actuator application examples