| Machine Tools |

|

| Machine Loader & Unloader Application Example | |

| Actuators | RCP4-SA6C/SA7C RCP2-GRM RCP2-RTCB |

| Controller | PCON-CA |

-

In the process of machining aluminum parts inside the machining center, ROBO Cylinders have been employed in loading & unloading the work parts.

-

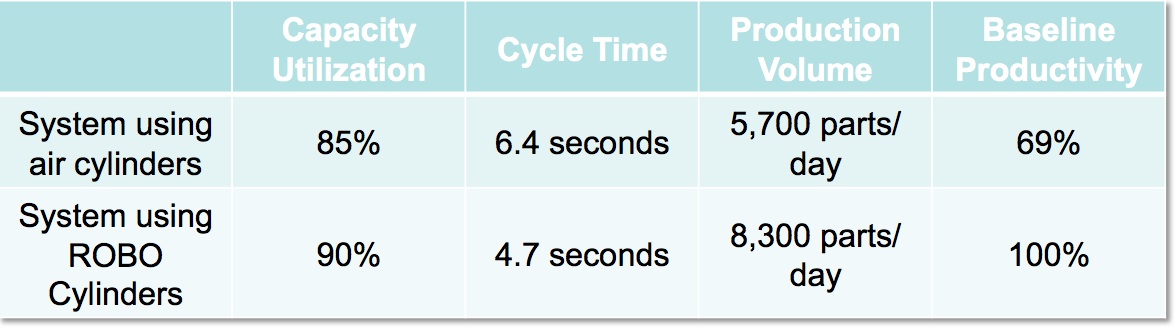

Traditionally, this task had been done manually but will be automated to increase production. Calculations were performed with regard to production volume and cycle time to determine whether using ROBO Cylinders or air cylinders would be most beneficial for the system. The results as shown in the table below indicate that 100% productivity can be realized with ROBO Cylinders while only 69% productivity can be realized with air cylinders.

Running 12 hours per day (60sec/min x 60min/hr x 12 hours = 43,200 seconds)

The number of work parts produced using air cylinders:

(43,200 seconds x 85%)÷6.4 seconds = 5,737 parts

The number of work parts produced using ROBO Cylinders:

(43,200 seconds x 90%)÷4.7 seconds = 8,272 parts