| No Specific Industries |

|

| Pressing a Pin into a Ring Application Example | |

| Actuator | RCP2-RA10C |

| Controller | PCON-CFA |

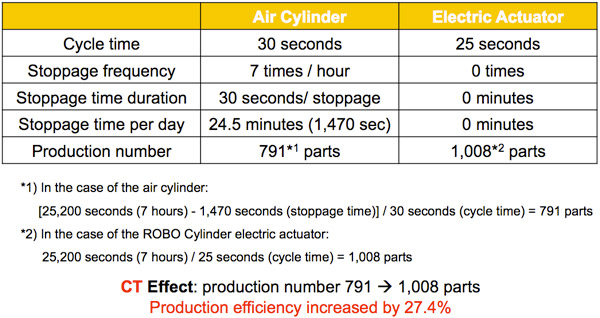

Reduction in Cycle Time/Choco Tei — CT Effects