| Automotive |

|

| Engine Parts Transfer Application Example | |

| Actuators | RCS3-SA8C, RCP2-SA5C, RCP2-GRM |

| Controllers | SCON, PCON |

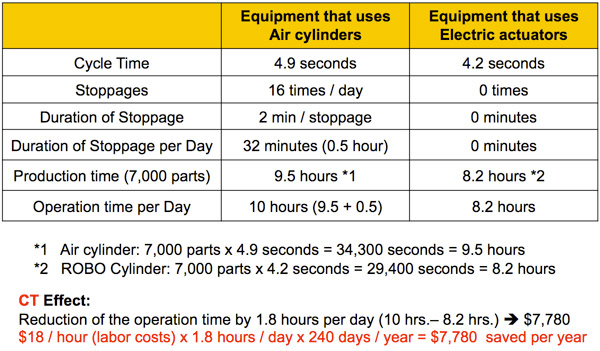

Reduction in Cycle Time/Choco Tei — CT Effects