| Inspection / Examination / Etc. |

|

| Heat Exchanger Hole Size Confirmation Application Example | |

| Robot | TT-A3-4040 |

| Controller | Built-in SEL controller |

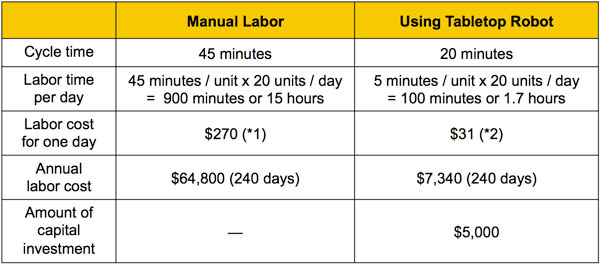

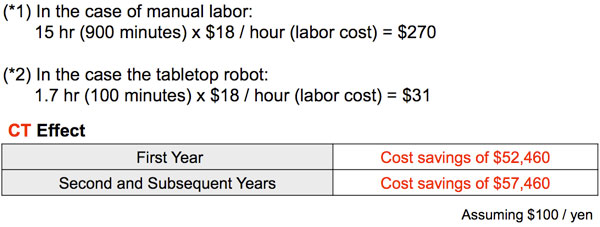

Reduction in Cycle Time/Choco Tei — CT Effects