| No Specific Industries |

|

| Alignment of the Resin Block Application Example | |

| Robot | RCA2-TWA4NA, RCS2-TWA5N |

| Controller | ACON, ASEP, MSEP, SCON |

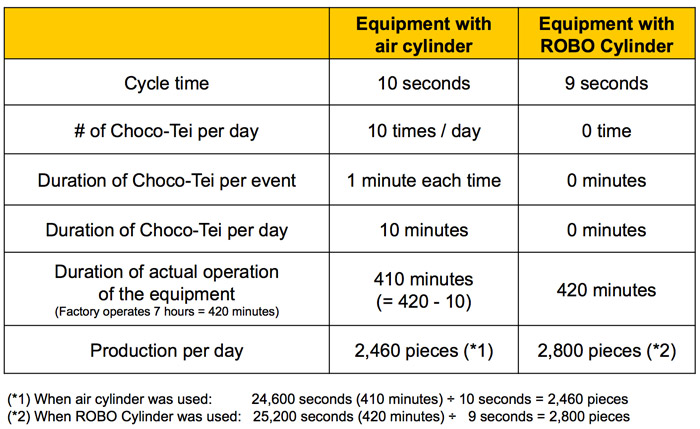

Because the resin blocks were misaligned by the impact of the air cylinder stop, they were operating it at a reduced speed. However, Choco-Tei was still occurring about 10 times a day because of the misalignment due to unstable speed. To rearrange the resin block and to recover from Choco-Tei, it took about 1 minute.

By replacing air cylinder to ROBO Cylinder, and adjusting the pressing force and acceleration/deceleration, they could increase the operating speed while minimizing the impact at the time of stop. In addition, Choco-Tei was reduced to near zero.

Reduction in Cycle Time/Choco Tei — CT Effects